Steelastic have launched three new products to further enhance their calenderless tire manufacturing equipment portfolio. These products enhance quality, safety and reduce waste of the tire component manufacturing process. Learn more about our newest products and see how you can implement them into your production line.

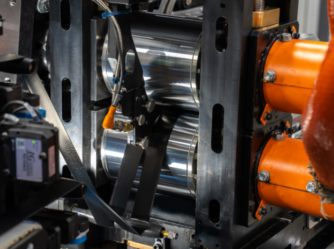

Double Roll Roller Die Hot Gum Edging System

The Double Roll Roller Die Hot Gum Edging System is an efficient and sustainable addition to the tire manufacturing line. It is Steelastic’s latest innovation in single compound gum application for steel belts. With this machine, the rubber is extruded via a die into a double roll system to produce highly toleranced gum material. The gum is then slit and applied to the steel belt, either top applied or wrapped. Unlike cold gum edging systems, the Double Roll Roller Die Hot Gum Edging System eliminates the use of a poly lining for a more sustainable product. It can be added to any tire component manufacturing line, even if it is not a Steelastic machine, to enhance quality, sustainability and operability.

Cold Feed Extrusion Splicing Unit

Cold feed extrusion systems need a continuous and consistent supply of rubber. If there is too little rubber, it can starve the machine. When there is too much rubber, it can have negative effects on the extrusion process. To prevent both of these issues, and to significantly improve operator safety, look to Steelastic’s Cold Feed Extrusion Splicing Unit. With this machine, two sheets of rubber are spliced together to make a continual feed of rubber to the extrusion process. When the end of a pallet of rubber feedstock draws near, the machine senses the trailing edge of rubber and automatically splices it to the leading-edge of rubber from the next pallet. During the splicing process, the feed conveyor stops automatically, and a uniform splice is made by metal fingers that punch through the material to reinforce the splice. The result is a very strong splice that will not pull apart. The system eliminates the need for operators to use hot knives, or to have to maneuver bulky rubber sheets. A consistent and strong splice, with minimal overlap provides, a better-quality end product.

CordSight Extrusion Thermal Inspection System

The CordSight Extrusion Thermal Inspection System provides a look inside extruded steel and textile reinforced rubber for missing cords and tension abnormalities. It uses infrared thermography to measure the surface temperature of extruded rubber. If there is a missing cord, the heat distribution will be uneven. At this point, the CordSight Extrusion Thermal Inspection System will raise an alarm to alert the operator, or automatically stop the process so the defect can be addressed. The machine looks for missing cords, missing rubber, tension abnormalities, uneven edge fill-out, and other extrusion defects. Save time, reduce waste, and enhance quality, by catching and correcting defects early in the process, before reaching the tire building machine.

Contact Steelastic Today

Ready to improve your tire component production? Contact Steelastic today for a quote. Improve the sustainability, quality and safety of your tire component manufacturing line.