EXTRUDED TEXTILE BODY PLY SYSTEMS

A flexible and efficient alternative to calendering and off-line processing equipment

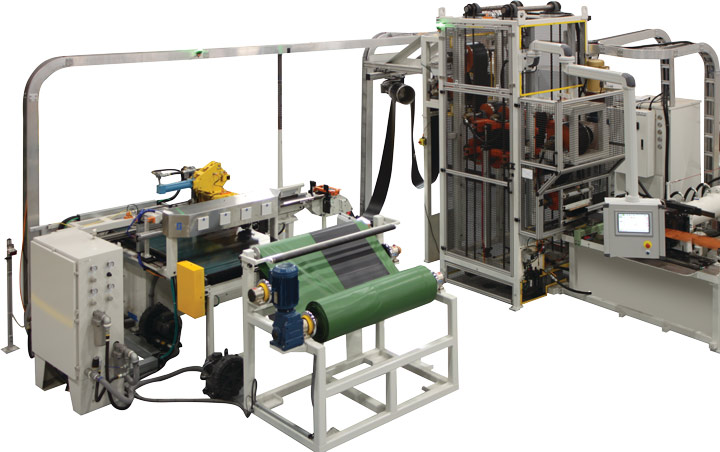

Start your new tire manufacturing plant without a calendering system using the Steelastic® Extruded Steel/Textile Body Ply System.

The Steelastic® Extruded Body Ply System makes it possible to produce steel and textile body ply material for passenger and specialty tires without calendering. Our proven precision splicing technology along with our high accuracy cord placement tooling combines to create a superior component prep solution. Laboratory trials have proven that tires produced with Steelastic’s extruded body ply perform as good or better than tires produced with calendered body ply. This innovative extrusion process is used to manufacture premium quality body ply material for:

Steelastic® Extruded Steel/Textile Body Ply System: Key Benefits

An extruded body ply system has benefits, such as:

- High flexibility enables multiple product codes per shift with fast changeovers

- One stop process from extrusion to wind-up eliminates additional handling and processing

- Significantly smaller footprint and lower capital investment than the calendering process

- Eliminates work in process materials and handling

- Requires only one operator per system

Body Ply System Features

Extruded body ply systems have features that contribute to their strength. See below:

- Processes single end textile cords with no possibility of crossed wires

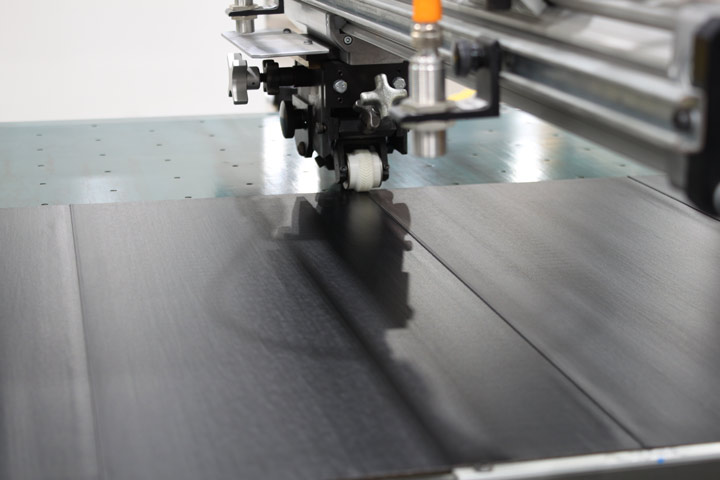

- Superior quality: precise width, gauge, and edge straightness

- Precision splice and ply angle

- Uniform cord tension

- Precise cord placement

- Elimination of 3-4 cord manufacturing splice

- Backwards compatibility with existing equipment – retrofit opportunities

- Ability to interface with customer Manufacturing Execution System (MES)

View our Extruded Steel/Textile Body Ply Machine PDF Data Sheet.